Description

Polyethylene (PE):

Elastic, impact-resistant, cold-resistant, this material is suitable for applications to -73° C. FDA approved for use in food processing.

Polypropylene (PP):

Neither aggressive substances nor temperatures up to +100° C can affect this material. FDA approved for use in food processing.

Polyacetal (POM):

This plastic is perfect for applications within a temperature zone of -43° C to +95° C with its high tensile force and low friction values. FDA approved for use in food processing.

Polyamid (PA):

Robust, pliable material with exceptional belt strength and a high level of notched impact strength. Temperature range from -45° C to +110° C

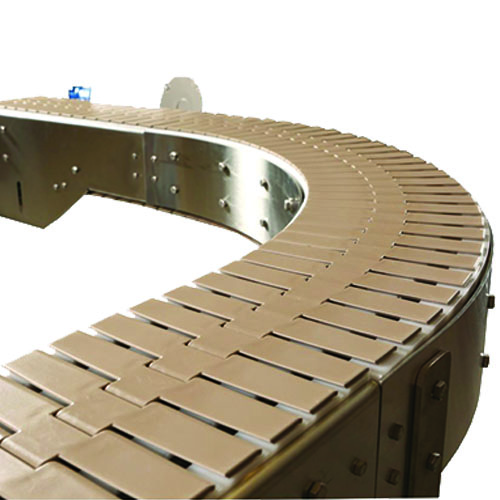

APPLICATION AREAS

-

- Conveyor machines

- Cooling towers

- Packaging equipment

- Storey conveyor

- Transport systems

MATERIALS

- Polyacetal

- Polyamide

- Polyethylene

- Polypropylene

Modular plastic conveyor belts offer many advantages over metal, fabric, or rubber belts, including:

- Longer belt life with less belt wear

- Simplified cleaning and maintenance

- Reduced risk of product loss or contamination

- Enhanced worker safety

- Zero need for lubrication or tensioning

Reviews

There are no reviews yet.